High-temperature applications – review and outlook

What was the project about?

Based on the need for development in the field of additive manufacturing of gas turbine components, a consortium of 9 partners was formed, who together wanted to leave behind the state of the art. From 2020 to 2022, the small and medium-sized companies CellCore, Friendship Systems, Contact Software and Optris from Berlin and Brandenburg worked together with the users Siemens & Siemens Energy and the research institutes TU Berlin, Fraunhofer IPK and the Federal Institute for Materials Research and Testing BAM.

The goals were, among others, the improvement of design approaches – and tools, an extended process understanding in the field of selective laser beam melting (PBF-LB/M), the prediction of creep properties, the evaluation of the influence of operating media or conditions on the change of properties, digital images of the process chain and much more.

What results have been achieved?

The work in the HTA project is divided into 3 strands, which are also used here to structure and summarize the results.

Additive manufacturing:

- Improvement of the industrial product development process through intensive cooperation between TU Berlin and Siemens Energy.

- Extension of the software Siemens NX with a plug-in of the company Friendship Systems for distortion reduction of PBF-LB/M components

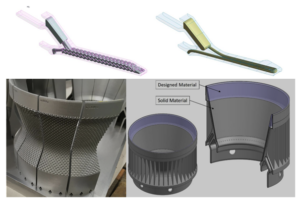

- Design and evaluation of new cooling concepts, which could only be realized by the degrees of freedom of additive manufacturing

- Concept development for large multi-laser systems and high-temperature laser powder bed systems

- Analysis and pre-development of acoustic defect detection during the build process as well as evaluation of OEM-independent camera systems for quality assurance

- The collaboration led to the further development of gas turbine combustor components

Figure 1 Selection of cooling concepts studied