Das WvSC vernetzt Menschen und Organisationen, ermöglicht Forschung und vorwettbewerblichen Austausch und unterstützt Menschen im Wandel der Arbeitswelt durch Weiterbildungsangebote.

Aus dem Verein

Aktuelle Nachrichten

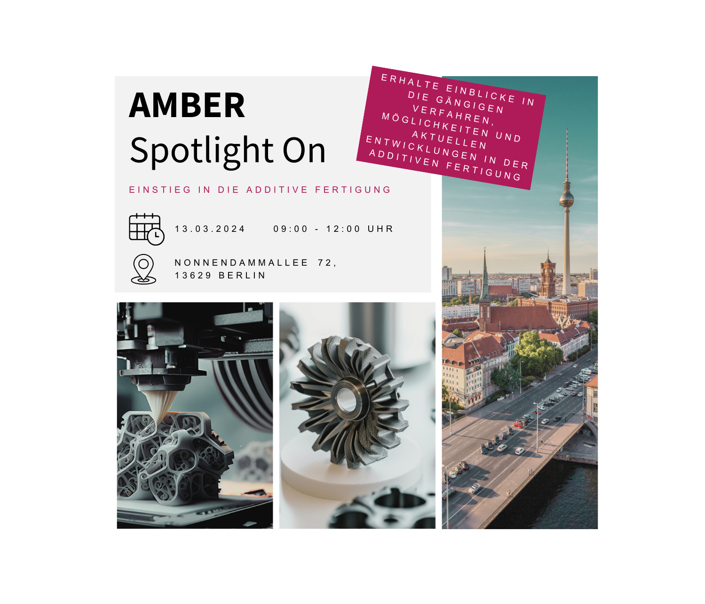

An dieser Stelle berichten wir aus unseren Projekten, von unseren Events und Bildungsangeboten, sowie über weitere Vereinsaktivitäten.